Sae 4140 aisi 4140 steel is a cr mo series chrome molybdenum series low alloy steel this material has high strength and hardenability good toughness small deformation during quenching high creep strength and long lasting strength at high temperature.

4130 stainless steel properties.

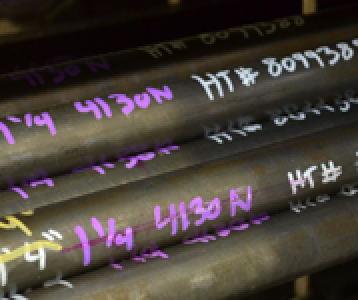

Aisi 4130 chromoly steel uns g41300 aisi 4130 steel uns g41300 also known as 4130 chromoly steel is a chrome molybdenum series low alloy steel with high strength toughness and hardenability usually used in quenched and tempered condition.

It is an exceptional welding steel being weldable in all commercial methods and is readily machined in its normalized tempered condition.

Aisi 4130 alloy steel has properties better than or similar to.

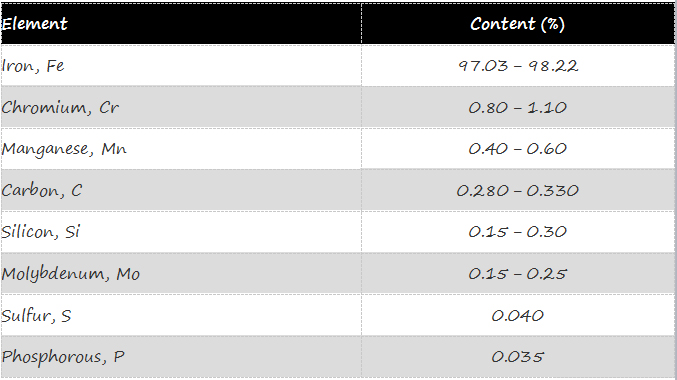

Astm 4140 steel is also commonly referred to as a chromoly steel or chrome moly steel containing nominally 0 28 0 33 carbon 0 8 1 1 chromium and 0 15 0 25 molybdenum.

Alloy 4130 is a widely used aircraft steel due to its weldability ease of fabrication and mild hardenability.

Aisi sae 4140 alloy steel can be made into round steel bar flat square steel bar steel.

What is 4130 steel.

4130 steel is a chromium molybdenum alloy steel and is considered a low carbon steel.

It is similar to 4140 steel which has a higher carbon level.

It is very useful for any mechanical engineer to be aware of 4130 steel properties.

The hardenability and weldability of alloy 4130 are considered equivalent to 8630 mil s 6250.

Sae aisi 4140 alloy steel.

4130 steel is easily cold.

Aisi 430 stainless steel ss430 straight chromium aisi 430 stainless steel ss430 is one of the conventional ferritic stainless steels with magnetic properties and good formability it has good corrosion resistance in a mild atmosphere mild oxidizing acid and organic acid.

4130 steel otherwise known as chromoly or chromium molybdenum steel alloy is made with 0 8 to 1 1 chromium and 0 15 to 0 25 molybdenum as strengthening agents.

Tempering of aisi 4130 steel can be performed at 399 to 566 c 750 to 1050 f depending on the desired strength level.

Steel properties make it a versatile metal especially mechanical properties such as high ductility good weldability and the fact it can be.

Some of the major applications of aisi 4130 alloy steel are in aircraft engine mounts and welded tubing.

It has a density of 7 85 g cm 3 0 284 lb in 3 and benefits from heat treatment hardening.

41xx steel is a family of sae steel grades as specified by the society of automotive engineers sae.

Alloy 4130 is also vacuum degassed to meet the magnetic particle inspection standards of ams 2301.

Alloying elements include chromium and molybdenum and as a result these materials are often informally referred to as chromoly steel common variant stylings include chrome moly cro moly crmo crmo cr moly and similar they have an excellent strength to weight ratio and are considerably.

.jpg)