Although ceramic is hard it is brittle and can break.

44 or 46 mm ceramic on ceramic hip surgery.

Listing a study does not mean it has been evaluated by the u s.

The purpose of this study was to evaluate the safety of a 4 mm thick ceramic liner and the outcomes of cementless total hip arthroplasty using a 44 or 46 mm metal shell and a.

The low wear low torque improved wettability and near absence of corrosion at the head neck taper junction all are factors that make these bearings an attractive.

In 1995 an improved alumina ceramic was developed that had increased purity and strength over the first generation materials.

Therefore a ceramic on poly replacement has the advantage of the lip and a ceramic on ceramic has the advantage of being tougher and permitting the use of a larger femoral head.

Reported that 65 of squeaking patients were not in a safe range of 25 10 cup anteversion and.

1 are there risk factors for ceramic component fracture following total hip replacement.

In a few ceramic hip replacements there has a catastrophic failure.

The ceramics used in hip replacement surgery are alumina ceramic and zirconia ceramic.

The clinical use of ceramic as a bearing surface dates back to the early 1970s.

36 mm ceramic on ceramic acetabular cup total hip replacement the safety and scientific validity of this study is the responsibility of the study sponsor and investigators.

Ceramic bearing surfaces are increasingly used for total hip replacement notwithstanding that concern is still related to ceramic brittleness and its possible mechanical failure.

The aim of this systematic review is to answer three questions.

The thin 4 mm ceramic liner did not increase the risk of ceramic fracture and did not affect the mid to long term results and survival of cementless total hip arthroplasty using 44 or 46 mm.

Metals and plastics can deform under stress.

Ceramic on ceramic articulation shows the lowest wear with a low incidence of osteolysis.

There is a rising concern about squeaking in ceramic on ceramic total hip arthroplasty with an incidence ranging from 0 5 to 20 many factors have been incriminated such as edge loading ceramic fracture third body particles and components malposition.

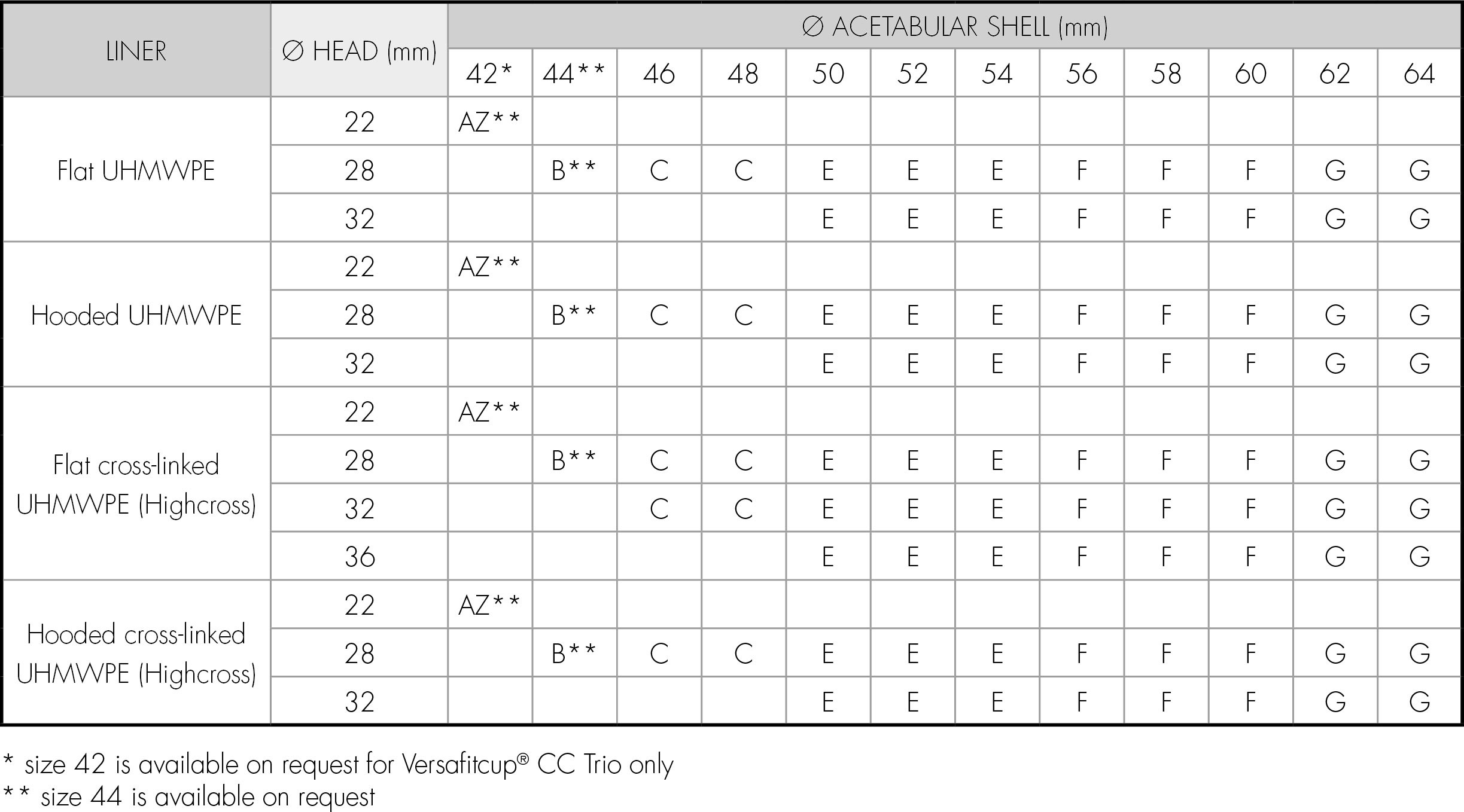

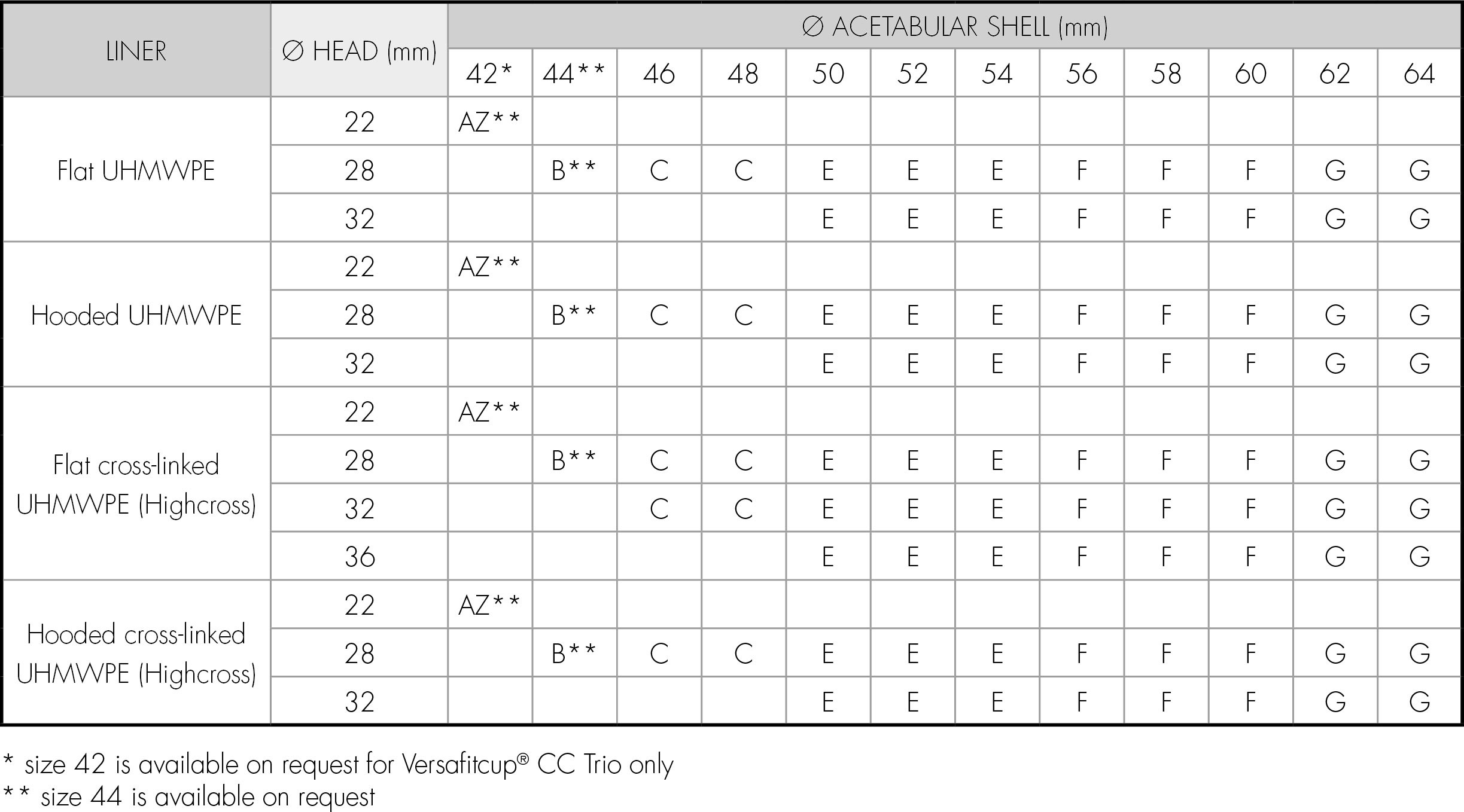

A small cup limits options regarding liner thickness and femoral implant size.

Ceramic on ceramic bearings have been used in total hip arthroplasty since the 1970s with routine clinical use of modern ceramics in the united states now at 20 years.

An x ray of the pelvic area showing a replacement hip.

The type of ceramic used in total hip replacement today is aluminum oxide also known as alumina.

Long lasting hip replacement is the main advantage of ceramic hip replacement systems.

Ceramic hip implants are among the newer types of prostheses being used for hip replacement offering greater resistance to damage and smooth movement of the joint.